1 月 . 24, 2025 05:47 Back to list

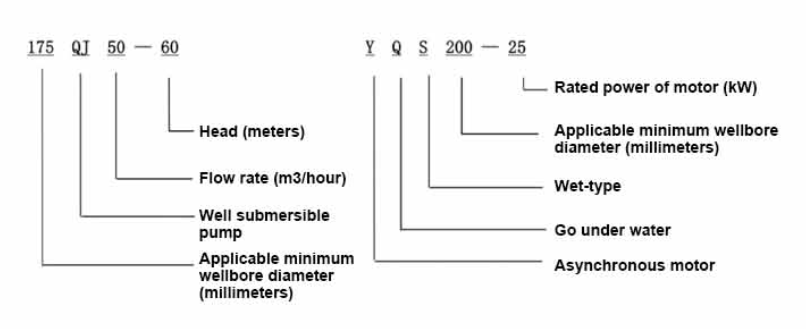

175QJ Deep Well Submersible Pump

Choosing the right submersible deep well pump is a decision of paramount importance, especially when managing water supply for agricultural, residential, or commercial purposes. The gravity of this choice is rooted in the pump's ability to deliver water effectively while ensuring reliability and longevity.

Switching focus to trustworthiness, the reliability of submersible deep well pumps is often validated by their certifications and adherence to stringent industry standards. Professionals in the field recommend looking for pumps that are UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certified, as these certifications indicate that the pumps meet rigorous safety and performance standards. Moreover, real-world experience emphasizes regular maintenance checks. Although many deep well pumps are engineered for durability, periodic inspections and service can preempt potential issues, ensuring continued efficiency and extending the pump’s lifespan. Key maintenance tasks include checking the electrical connections, inspecting pump and well components for any signs of wear or damage, and testing the motor for proper operation. To summarize, investing in a high-quality submersible deep well pump is a prudent decision for anyone reliant on deep well water extraction. The combination of robust construction, expert sizing, and selection, alignment with authoritative manufacturers, and regular maintenance protocols culminate in a trusted water delivery system that expertly supports day-to-day water needs. By paying close attention to these critical factors, one ensures the water supply remains uninterrupted, efficient, and cost-effective, underpinning the broader environmental and economic benefits of using a well-structured submersible deep well pumping system.

Switching focus to trustworthiness, the reliability of submersible deep well pumps is often validated by their certifications and adherence to stringent industry standards. Professionals in the field recommend looking for pumps that are UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certified, as these certifications indicate that the pumps meet rigorous safety and performance standards. Moreover, real-world experience emphasizes regular maintenance checks. Although many deep well pumps are engineered for durability, periodic inspections and service can preempt potential issues, ensuring continued efficiency and extending the pump’s lifespan. Key maintenance tasks include checking the electrical connections, inspecting pump and well components for any signs of wear or damage, and testing the motor for proper operation. To summarize, investing in a high-quality submersible deep well pump is a prudent decision for anyone reliant on deep well water extraction. The combination of robust construction, expert sizing, and selection, alignment with authoritative manufacturers, and regular maintenance protocols culminate in a trusted water delivery system that expertly supports day-to-day water needs. By paying close attention to these critical factors, one ensures the water supply remains uninterrupted, efficient, and cost-effective, underpinning the broader environmental and economic benefits of using a well-structured submersible deep well pumping system.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail