10 月 . 19, 2024 11:55 Back to list

3 phase submersible motor

Understanding 3% Phase Submersible Motors A Comprehensive Overview

Submersible motors are pivotal in various industrial and agricultural applications where the efficiency of fluid handling is crucial. Among the different types of submersible motors, 3-phase submersible motors stand out due to their high efficiency, robustness, and ability to operate under challenging conditions. This article delves into the characteristics, applications, advantages, and considerations of 3-phase submersible motors.

What is a 3-Phase Submersible Motor?

A 3-phase submersible motor is an electric motor designed to operate submerged in fluid. It typically comprises a three-phase induction motor sealed in a waterproof casing to protect it from the environment. The motor converts electrical energy into mechanical energy, which is then used to pump water or other fluids from depths underground or underwater.

Characteristics of 3-Phase Submersible Motors

1. Construction These motors are generally made from corrosion-resistant materials to withstand harsh environments. The watertight enclosure is essential, as it allows the motor to function while submerged without risk of electrical failure.

2. Efficiency 3-phase motors are known for their superior efficiency compared to single-phase motors. Their design minimizes energy losses, making them ideal for continuous operation in demanding applications.

3. Power Supply The three-phase power supply allows for a more balanced and stable operation. This results in smoother torque delivery, reducing vibration and mechanical wear in the motor.

4. Starting Torque They provide high starting torque, essential in applications where the pump needs to start under load.

Applications of 3-Phase Submersible Motors

3-phase submersible motors are widely used in several domains, including

- Agriculture Irrigation systems often employ these motors to pump groundwater efficiently, ensuring a steady and reliable source of water for crops.

- Water Supply Municipal water supply systems use submersible motors to extract water from deep wells, ensuring adequate water pressure and supply for residential and commercial use.

- Wastewater Management In sewage treatment plants, submersible motors are integral in pumping wastewater, allowing for effective management and processing of sewage

.3 phase submersible motor

- Industrial Applications These motors are prevalent in industries for various fluid transportation processes, such as cooling water circulation and chemical processing.

Advantages of 3-Phase Submersible Motors

1. Higher Efficiency The efficiency benefit reduces energy costs over time, making these motors more economical for long-term use.

2. Lower Maintenance Due to their durable construction and sealed designs, 3-phase submersible motors typically require less maintenance than their open counterparts.

3. Reliability Their robust design ensures longevity and reliability, critical in applications where the continuous operation is necessary.

4. Versatility They can handle various liquids, including abrasive or corrosive fluids, depending on the material used in the motor’s construction.

Considerations When Choosing a 3-Phase Submersible Motor

When selecting a 3-phase submersible motor, several factors must be considered

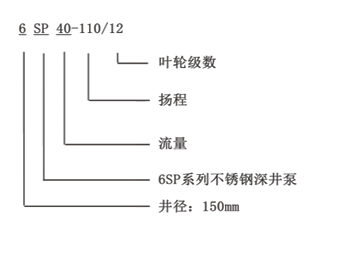

- Depth and Diameter of the Well It’s crucial to choose a motor that suits the specific depth and diameter of the well to ensure optimal performance.

- Fluid Characteristics The fluid’s viscosity, temperature, and chemical composition can affect the motor’s performance and lifespan.

- Power Supply Compatibility Ensure that the motor is compatible with the available power supply and meets local electrical codes.

- Pump Power and Flow Rate Requirements Calculate the necessary horsepower and flow rate for the intended application to select the appropriately sized motor.

In conclusion, 3-phase submersible motors are vital components in various applications that require reliable, efficient fluid handling. Their design offers significant advantages in energy efficiency, maintenance, and overall reliability. By understanding the characteristics and applications of these motors, users can make informed decisions that enhance operational effectiveness and sustainability in their water management practices. As technology progresses, we can expect even more efficient and advanced submersible motor designs to emerge, further aiding in our quest for effective water resource management.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail