1 月 . 20, 2025 13:57 Back to list

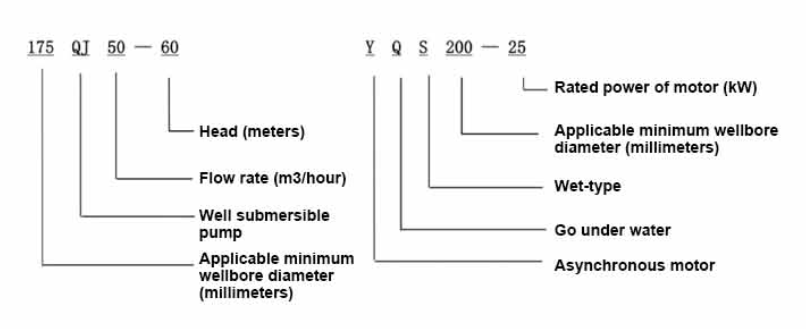

175QJ Deep Well Submersible Pump

When it comes to deep well submersible pumps, the technology is as robust as the needs they're designed to meet. These pumps are an integral part of water supply systems across various industries, offering unparalleled efficiency in extracting water from deep wells. Their utility spans agricultural applications, municipal water supply, and even residential settings where groundwater is the primary resource.

For those exploring the installation and maintenance landscape, it’s imperative to recognize the importance of proper installation. The well configuration must be assessed accurately to ensure that the pump is submerged correctly and that the discharge pipe is positioned to prevent backflow or contamination. Regular maintenance involves checking electrical components, testing motor insulation, and performing regular water quality checks to prevent fouling. From an authority perspective, it’s worth noting that many leading industry bodies and experts emphasize the significance of using certified products. Compliance with standards such as ISO 9001 ensures product quality and reliability. Testimonials from other industry professionals reveal that adherence to such certifications not only guarantees product safety but also enhances the overall efficiency and performance of the installation. Trustworthiness in deep well submersible pumps often comes down to the manufacturer. Brands with a long-standing reputation tend to offer better customer support, warranties, and replacement policies. In my experience, aligning with manufacturers known for their innovation and customer-centric approach ensures that clients receive dependable solutions tailored to their unique needs. In conclusion, the decision to invest in a deep well submersible pump should involve a comprehensive understanding of one’s requirements, an assessment of product specifications, and a commitment to ongoing maintenance. With the right choice, users can enjoy a seamless and dependable water supply system built to meet the increasingly demanding challenges of today. Ensuring the longevity and efficiency of your deep well submersible pump depends not only on the initial purchase but also on the expertise employed during installation and maintenance.

For those exploring the installation and maintenance landscape, it’s imperative to recognize the importance of proper installation. The well configuration must be assessed accurately to ensure that the pump is submerged correctly and that the discharge pipe is positioned to prevent backflow or contamination. Regular maintenance involves checking electrical components, testing motor insulation, and performing regular water quality checks to prevent fouling. From an authority perspective, it’s worth noting that many leading industry bodies and experts emphasize the significance of using certified products. Compliance with standards such as ISO 9001 ensures product quality and reliability. Testimonials from other industry professionals reveal that adherence to such certifications not only guarantees product safety but also enhances the overall efficiency and performance of the installation. Trustworthiness in deep well submersible pumps often comes down to the manufacturer. Brands with a long-standing reputation tend to offer better customer support, warranties, and replacement policies. In my experience, aligning with manufacturers known for their innovation and customer-centric approach ensures that clients receive dependable solutions tailored to their unique needs. In conclusion, the decision to invest in a deep well submersible pump should involve a comprehensive understanding of one’s requirements, an assessment of product specifications, and a commitment to ongoing maintenance. With the right choice, users can enjoy a seamless and dependable water supply system built to meet the increasingly demanding challenges of today. Ensuring the longevity and efficiency of your deep well submersible pump depends not only on the initial purchase but also on the expertise employed during installation and maintenance.

Next:

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail