1 月 . 06, 2025 19:24 Back to list

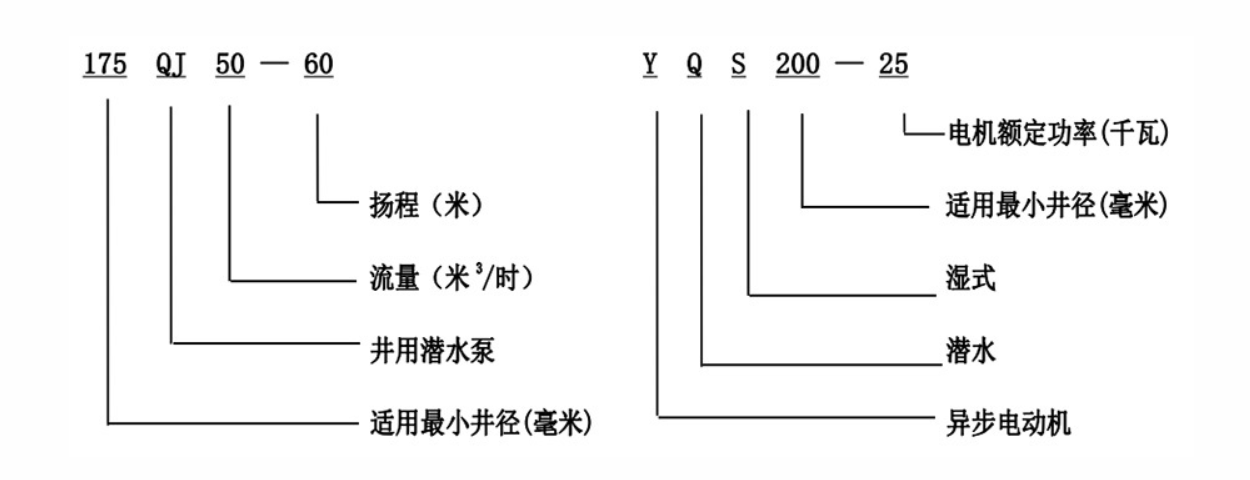

175QJ Deep Well Submersible Pump

Deep well pumps, often categorized as submersible pumps, are essential components in many industries, especially those requiring the management and distribution of water from deep underground sources. With their capacity to function in challenging environments, deep well pumps have proven indispensable in agricultural, municipal, and industrial applications.

Experience is paramount when selecting and maintaining a deep well pump. Users often encounter challenges such as variable water levels or corrosive environments. It is crucial to choose a pump made from high-quality, durable materials such as stainless steel or cast iron, which offer resistance to rust and wear over time. Real-world experiences suggest that regular maintenance, including checking pressure levels and ensuring the integrity of electrical components, extends a pump’s functional life considerably. Experienced users highlight the importance of understanding your specific water table’s characteristics to select a pump with the appropriate horsepower and pressure specifications.

Expertise in the engineering and installation of deep well pumps cannot be overstated. The proper installation is fundamental to the performance and longevity of these systems. Professionals in the field utilize advanced techniques for installation, often including precise measurements for pump placement to avoid issues like cavitation. Furthermore, experts emphasize using advanced control systems, which can automatically adjust pump operation based on water demand, thereby improving efficiency and reducing wear and tear on components.

When considering authoritativeness, leading manufacturers such as Grundfos, Franklin Electric, and Xylem are renowned for producing reliable deep well pumps that set industry standards. These companies conduct extensive research and development to innovate pump technology continually. Their products undergo rigorous testing to ensure they can withstand extreme conditions commonly encountered in deep well applications. By choosing a product from a reputable manufacturer, customers gain access to a wealth of resources, including detailed documentation, customer support, and extensive warranty options, enhancing the reliability and performance of their pumps.

Trustworthiness is a critical factor that encompasses both product and service reliability. Industry reviews and certifications play a significant role in establishing the trustworthiness of a deep well pump. For instance, certifications such as ISO standards indicate that a product meets high-quality manufacturing processes and safety standards. Trustworthy reviews from industry professionals and consumers provide insight into a product’s long-term performance and reliability. Customers should seek products with overwhelmingly positive feedback that highlight consistent performance, durability, and specialist support.

In summary, selecting the right deep well pump involves a blend of user experience, specialized expertise, authoritative manufacturing, and trustworthy product performance. Potential buyers should consider these factors to ensure their chosen pump meets their specific needs while also delivering longevity and dependable service. A well-researched investment in a high-quality deep well pump not only ensures efficient water management but also offers peace of mind and value for years to come.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail