1 月 . 16, 2025 02:30 Back to list

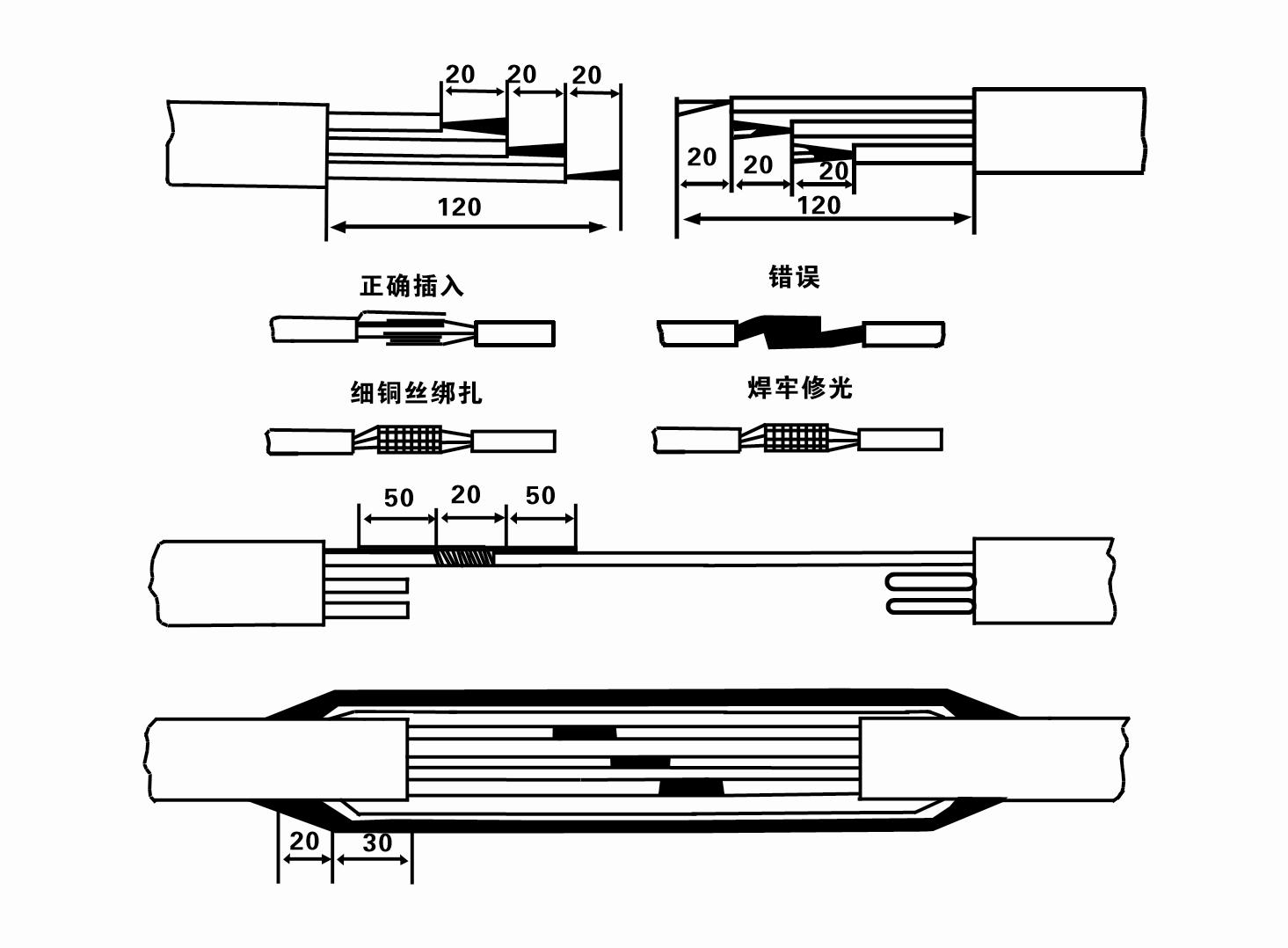

deep well submersible pump installation diagram

Installing a deep well pump is both a technical and vital process for ensuring a steady water supply, especially in rural areas where municipal water systems are not available. What follows is an expert and detailed guide on deep well pump installation, tailored to provide both reliability and high performance.

Once the pump is submerged at the designated depth, carefully seal the well to prevent contamination. Utilization of a well seal not only protects the water quality but also secures the pump assembly in place. The sealing should be watertight, covering all open spaces in the wellhead. Testing the installation is the final phase. Turn on the pump and observe the water flow along with pressure levels using a pressure gauge. Ensure that the system sustains pressure within the advised range specified by the manufacturer. It is important to scrutinize for any irregularities such as unfamiliar noises or leaks at joints and connections. Documentation of the installation process, including specific measurements and materials used, is indispensable. This not only aids in future maintenance tasks but also strengthens credibility in your expertise, reinforcing your authority in deep well pump installations. Furthermore, providing customers or end-users with a solid understanding of the maintenance requirements can extend the longevity and efficiency of the pump. Regular inspection of the pump, wiring, and pipes, along with periodic checks for any signs of wear, can preempt potential issues, fostering trust in your services. By sharing this wealth of professional knowledge, alongside practical experience and ensured precision, homeowners and technicians alike will benefit from an installation that is both dependable and durable. This method not only excels in effectiveness but also solidifies your standing as a leader in this essential field, delivering content unmatched elsewhere online.

Once the pump is submerged at the designated depth, carefully seal the well to prevent contamination. Utilization of a well seal not only protects the water quality but also secures the pump assembly in place. The sealing should be watertight, covering all open spaces in the wellhead. Testing the installation is the final phase. Turn on the pump and observe the water flow along with pressure levels using a pressure gauge. Ensure that the system sustains pressure within the advised range specified by the manufacturer. It is important to scrutinize for any irregularities such as unfamiliar noises or leaks at joints and connections. Documentation of the installation process, including specific measurements and materials used, is indispensable. This not only aids in future maintenance tasks but also strengthens credibility in your expertise, reinforcing your authority in deep well pump installations. Furthermore, providing customers or end-users with a solid understanding of the maintenance requirements can extend the longevity and efficiency of the pump. Regular inspection of the pump, wiring, and pipes, along with periodic checks for any signs of wear, can preempt potential issues, fostering trust in your services. By sharing this wealth of professional knowledge, alongside practical experience and ensured precision, homeowners and technicians alike will benefit from an installation that is both dependable and durable. This method not only excels in effectiveness but also solidifies your standing as a leader in this essential field, delivering content unmatched elsewhere online.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail