1 月 . 23, 2025 05:24 Back to list

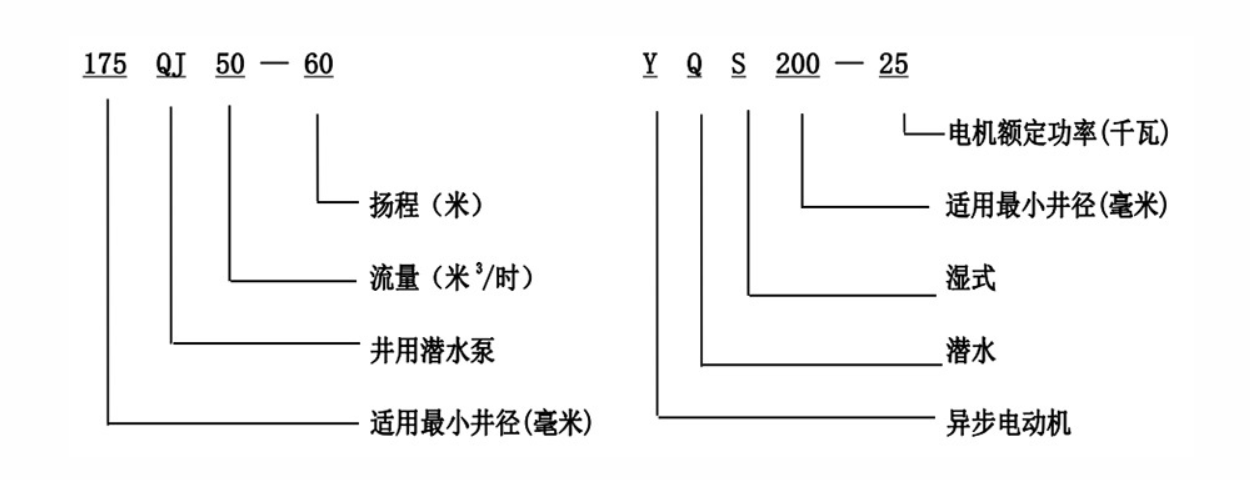

175QJ Deep Well Submersible Pump

Deep well pumps submersible are critical components in a myriad of water management systems due to their efficiency and reliability in accessing water resources from significant depths. As a seasoned professional in the field, understanding the intricacies of these pumps is crucial for both selecting and maintaining the optimal system for any application.

For those in the field, expertise with these pumps often begins with a comprehensive understanding of the materials used in their construction. Stainless steel is favored for its corrosion resistance—a critical factor given the pump's constant exposure to water. Additionally, advanced models incorporate high-quality bearings and a robust impeller design to withstand abrasive materials often found in well water. Authoritativeness in submersible pump installation and maintenance can drastically extend the life of the system. Proper installation is paramount; incorrect placement can lead to issues like sand intrusion or pump misalignment. Experts recommend routine inspections and maintenance, which include checking the pump’s operational efficiency, electrical connections, and potential blockages in the system. Professionals often employ diagnostic tools such as flow meters and pressure gauges to ensure optimal performance. Trustworthiness in choosing the right submersible deep well pump often relates to the brand and model reputation. Renowned manufacturers provide detailed product specifications and performance guarantees. This assurance, combined with positive customer feedback and service records, helps narrow down choices amid a crowded market. In conclusion, deep well submersible pumps are indispensable tools for efficient water management, offering both the power and reliability needed for a variety of applications. Mastery of these systems demands a blend of knowledge on pump specifications, installation techniques, and maintenance best practices. Engaging with trusted manufacturers and relying on professional insights ensures that users receive the most benefit from their investment while maintaining a robust, uninterrupted water supply.

For those in the field, expertise with these pumps often begins with a comprehensive understanding of the materials used in their construction. Stainless steel is favored for its corrosion resistance—a critical factor given the pump's constant exposure to water. Additionally, advanced models incorporate high-quality bearings and a robust impeller design to withstand abrasive materials often found in well water. Authoritativeness in submersible pump installation and maintenance can drastically extend the life of the system. Proper installation is paramount; incorrect placement can lead to issues like sand intrusion or pump misalignment. Experts recommend routine inspections and maintenance, which include checking the pump’s operational efficiency, electrical connections, and potential blockages in the system. Professionals often employ diagnostic tools such as flow meters and pressure gauges to ensure optimal performance. Trustworthiness in choosing the right submersible deep well pump often relates to the brand and model reputation. Renowned manufacturers provide detailed product specifications and performance guarantees. This assurance, combined with positive customer feedback and service records, helps narrow down choices amid a crowded market. In conclusion, deep well submersible pumps are indispensable tools for efficient water management, offering both the power and reliability needed for a variety of applications. Mastery of these systems demands a blend of knowledge on pump specifications, installation techniques, and maintenance best practices. Engaging with trusted manufacturers and relying on professional insights ensures that users receive the most benefit from their investment while maintaining a robust, uninterrupted water supply.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail