1 月 . 06, 2025 11:10 Back to list

deep well submersible pump installation

Installing a deep well submersible pump requires precision and expertise, ensuring optimal performance and longevity. It begins with a thorough understanding of the well's specifications, as these influence the pump selection and installation process. A professional approach to this installation integrates experience, technical knowledge, and adherence to safety protocols, establishing confidence in both the installer and the equipment's reliability.

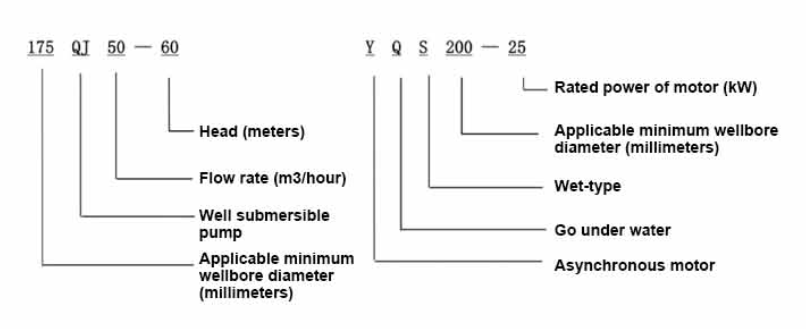

The initial step involves determining the appropriate pump size, which demands an in-depth analysis of the well's depth, diameter, and water yield. Choosing the correct horsepower based on these factors is crucial for maintaining efficient operation and preventing premature wear. A pump with insufficient power can lead to inadequate water delivery, while an oversized pump may result in unnecessary energy consumption and increased operational costs.

Once the suitable pump is selected, the focus shifts to preparing the well site. This includes ensuring the workspace is free from debris and that proper safety measures are in place to protect both the workers and the equipment. It’s essential to confirm that all electrical components meet regulatory standards, creating a reliable and secure electrical connection to the power source. Using corrosion-resistant materials for wiring enhances durability and reduces the risk of failure.

During the physical installation, the submersible pump is carefully lowered into the well, avoiding any contact with the well walls to prevent damage. Precision in aligning the pump is imperative, as it must remain vertical to function correctly. Sealing the top of the well with an appropriate cap prevents contaminants from entering, safeguarding the water quality and prolonging the lifespan of the pump.

deep well submersible pump installation

The pipework plays a significant role in the pump’s efficiency. Ensuring that pipes are correctly sized and sealed minimizes the risk of leaks and maintains pressure levels conducive to efficient water delivery. For added reliability, installing a check valve prevents backflow, which can lead to pressure fluctuations and pump cycling.

After installation, conducting a thorough system test verifies that the pump operates seamlessly. Monitoring initial water flow rates and observing any anomalies allows for immediate adjustments. An expert installer takes note of the system’s electrical current draw, ensuring it aligns with specifications. This step establishes the baseline performance metrics for future maintenance.

Regular maintenance is integral to the deep well submersible pump's longevity. This includes periodic inspections to assess wear on moving parts, checks on electrical connections, and ensuring that the pump remains free from obstructions. Maintenance schedules should be documented, alongside any repair or adjustments, reinforcing an authoritative record of the pump's operational history.

By engaging with seasoned professionals who demonstrate expertise and a rigorous adherence to safety and operational guidelines, the integrity and trustworthiness of the installation process are elevated. Such diligence not only maximizes the performance of the pump but also fortifies customer trust in the efficacy of the well system, ensuring a reliable water supply for years.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail