1 月 . 07, 2025 10:03 Back to list

Expert's Guide to Deep Well Submersible Pump Installation

Installing a deep well submersible pump involves technical expertise and precision, making it essential for professionals and DIY enthusiasts to understand the intricacies of the process. With decades of experience in the field, I am excited to share a comprehensive guide that combines hands-on experience with authoritative insights, ensuring you approach the installation with confidence.

The selection and installation of a deep well submersible pump begin with understanding the unique characteristics of your well. Start by evaluating the well's depth, diameter, and water table level. These parameters are crucial in selecting a pump that matches the depth capacities and flow requirements specific to your property. An incorrect choice can lead to inefficient operation and potential damage to the pump system.

Before installation, gather the necessary tools and components the submersible pump, appropriate length and diameter of drop pipe, electrical wires, control box, safety rope, torque arrestors, and a check valve. Utilizing high-quality materials not only ensures longevity but also augments the system’s reliability. The electrical wires, in particular, must be suited for submersible applications, often requiring direct burial cables that resist moisture and ground pressure.

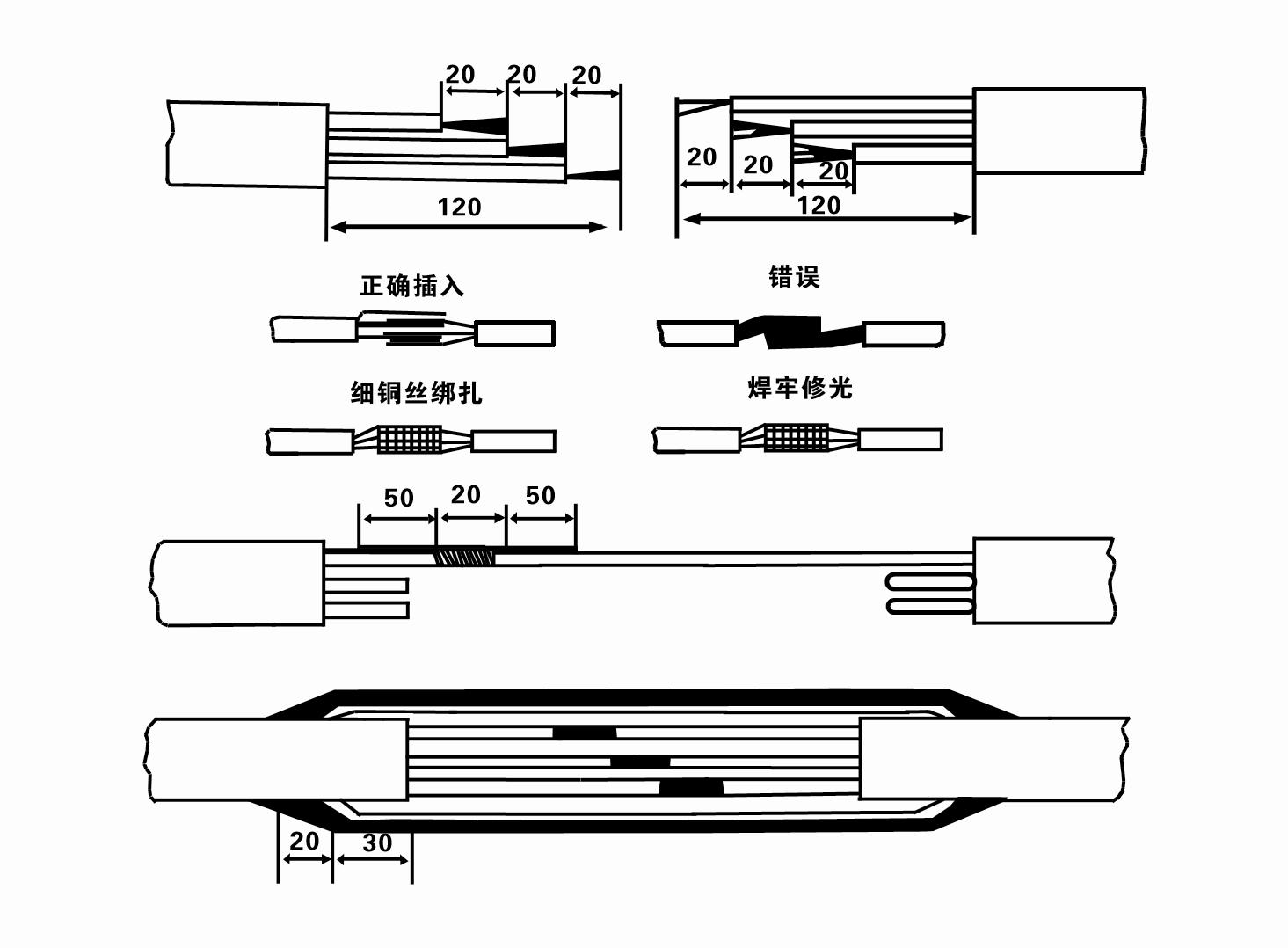

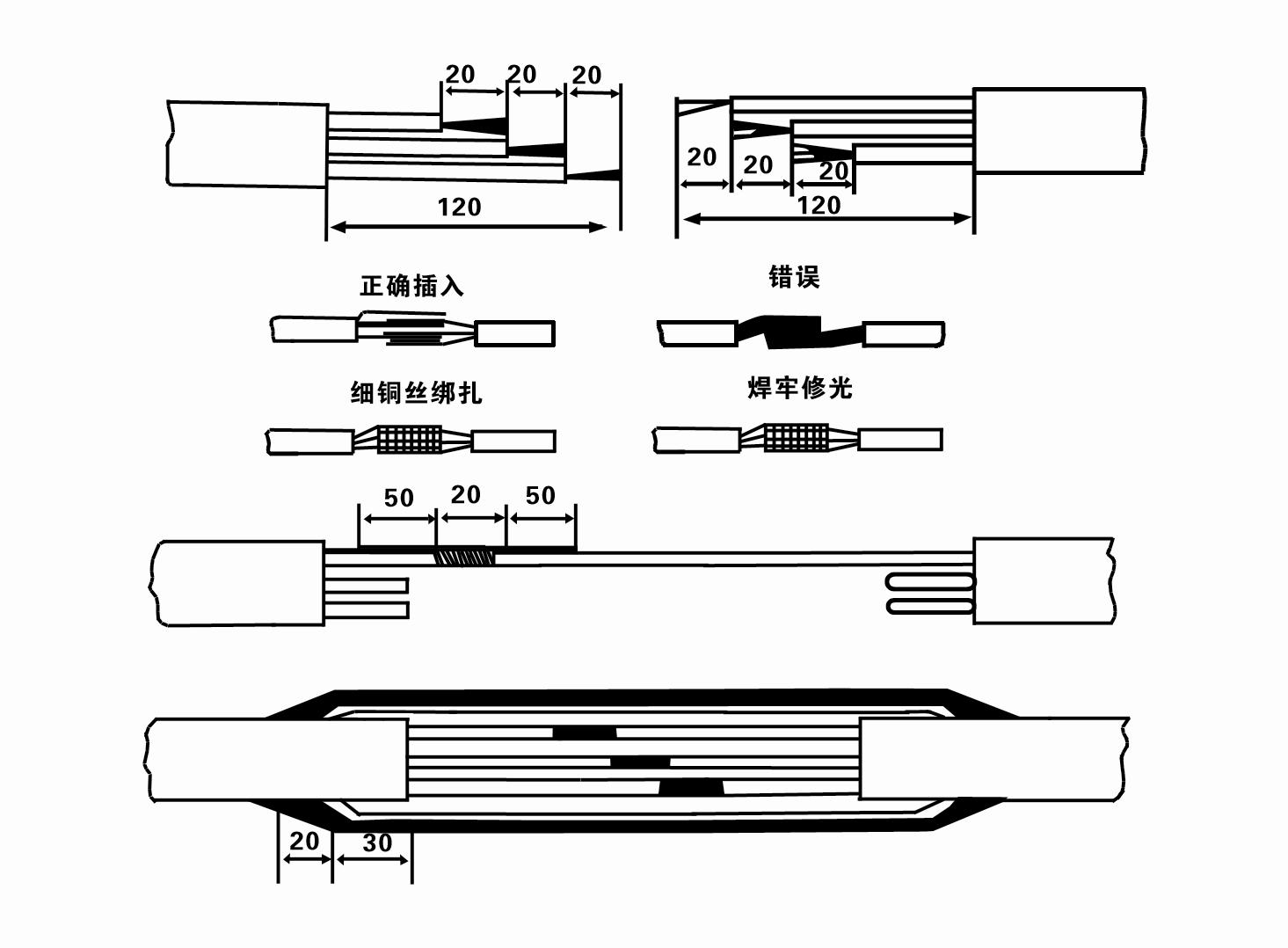

Begin by attaching the pump to the poly or PVC drop pipe. Securely connect the electrical wires to the pump, ensuring that each wire is correctly color-coded to corresponding terminals. This guarantees that the motor will operate correctly, minimizing the risk of short circuits. Use waterproof splice kits to protect these connections from water exposure. The torque arrestor, positioned just above the pump, helps limit lateral movements, preventing damage to the well casing and drop pipe due to the pump's kinetic energy.

deep well submersible pump installation

The pump, with its connected pipes and wires, must be slowly and carefully lowered into the well. Employing a safety rope, affixed to the pump, offers an additional layer of security against accidental drops. This step requires precision to avoid snagging or misalignment, both of which could result in compromised water flow and increased wear on the pump components.

Once the pump is in place, install a check valve at the top of the drop pipe. The check valve is crucial as it prevents water from siphoning back into the well, thereby safeguarding the pump from frequent cycling and potential burnout. Plug the wires into the control box, ensuring it’s housed in a weatherproof enclosure, and connected to a reliable power source. It is advisable to conduct electrical tests to confirm voltage and phase alignments are within the manufacturer’s specified limits.

Successful submersible pump installations also rely on regular maintenance. Performing periodic inspections of the system can preempt wear-and-tear issues, from clogging due to sediment build-up to electrical inefficiencies. Ensure that all safety standards and local regulations are adhered to, as non-compliance can lead to legal penalties and personal liability issues.

The successful installation of a deep well submersible pump combines expert selection, methodological placement, and rigorous maintenance. By adhering to these guidelines, you set the stage for a long-lasting, efficient water supply system that underpins the wellbeing of your home or business, demonstrating both expertise and trustworthiness in managing such a vital resource.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail