1 月 . 26, 2025 02:18 Back to list

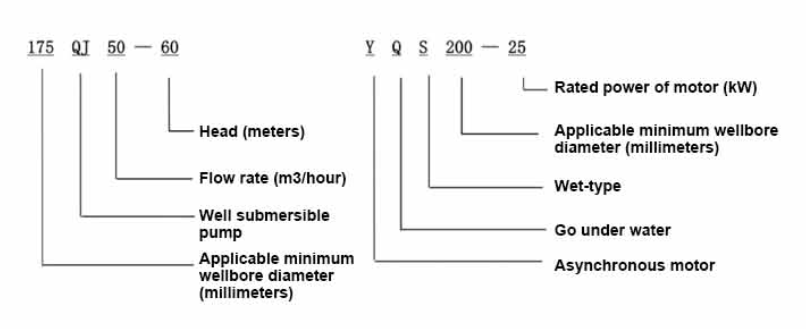

175QJ Deep Well Submersible Pump

Deep well pumps and submersible pumps are integral to the efficient extraction and management of groundwater resources. Discerning the differences between these two vital pumping mechanisms can be crucial for professionals looking to optimize their water extraction systems. This article delves into the distinct characteristics and applications that set deep well pumps apart from submersible pumps, providing insights from industry experts to ensure you make an informed decision.

From an energy consumption perspective, experts often highlight that submersible pumps tend to be more energy-efficient. This efficiency arises from the direct placement in the water, which reduces friction losses and the energy intensive task of lifting water via a long shaft, as required in deep well pumps. Despite these differences, the choice between a deep well and a submersible pump largely depends on specific application needs and environmental conditions. For instance, areas prone to flooding may benefit from submersible pumps due to their water-resistant design. Conversely, deep well pumps may be favored in regions where accessing the motor for maintenance without disrupting operations is crucial. Authoritative sources also stress the importance of considering well depth and yield, water quality, and maintenance capabilities. Consulting with experienced professionals can provide valuable insights tailored to specific site conditions, ensuring the chosen pump type aligns with operational demands and budget constraints. Ultimately, understanding the nuances between deep well and submersible pumps empowers decision-makers to select the most appropriate technology for their water management needs. This expertise not only optimizes resource extraction but also contributes to sustainable water use, reducing environmental impact and operational costs over the long term.

From an energy consumption perspective, experts often highlight that submersible pumps tend to be more energy-efficient. This efficiency arises from the direct placement in the water, which reduces friction losses and the energy intensive task of lifting water via a long shaft, as required in deep well pumps. Despite these differences, the choice between a deep well and a submersible pump largely depends on specific application needs and environmental conditions. For instance, areas prone to flooding may benefit from submersible pumps due to their water-resistant design. Conversely, deep well pumps may be favored in regions where accessing the motor for maintenance without disrupting operations is crucial. Authoritative sources also stress the importance of considering well depth and yield, water quality, and maintenance capabilities. Consulting with experienced professionals can provide valuable insights tailored to specific site conditions, ensuring the chosen pump type aligns with operational demands and budget constraints. Ultimately, understanding the nuances between deep well and submersible pumps empowers decision-makers to select the most appropriate technology for their water management needs. This expertise not only optimizes resource extraction but also contributes to sustainable water use, reducing environmental impact and operational costs over the long term.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail