8 月 . 16, 2024 15:06 Back to list

Exploring the Cost of Submersible Pumps for Various Applications and Needs

Understanding Submerged Pump Prices Factors and Considerations

Submerged pumps, also known as submersible pumps, are a critical component in various industries, including agriculture, mining, municipal water systems, and wastewater management. They are designed to operate while fully submerged in the liquid they are pumping, making them essential for many applications where surface pumps would be inefficient or ineffective. However, when considering the purchase of a submerged pump, one of the primary areas of concern for buyers is the price. This article explores the various factors influencing submerged pump prices and how to make informed purchasing decisions.

1. Type and Specification

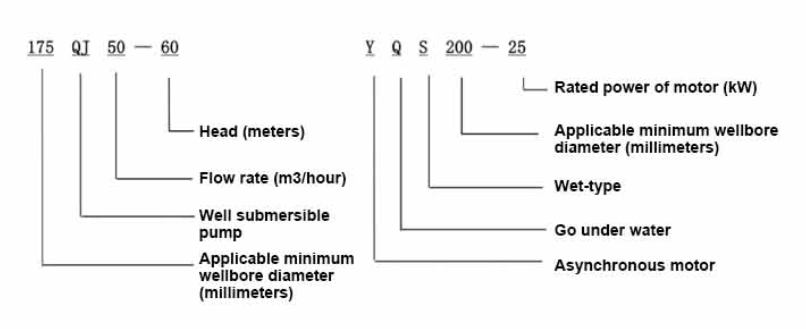

The price of submerged pumps can vary widely based on their type and specifications. There are numerous types of submersible pumps, including sewage pumps, drainage pumps, and well pumps, each designed for specific applications. The size, power, and material of the pump also play a significant role in determining the price. For instance, a pump made for heavy-duty industrial use will typically costs more than a residential unit due to its robust construction and higher capacity.

2. Brand and Quality

Brand reputation substantially affects the price of submerged pumps. Established manufacturers that are known for quality and reliability often charge a premium for their products. Buying from reputable brands may result in a higher initial investment but can be more cost-effective in the long run due to lower maintenance costs and greater longevity. Conversely, lesser-known brands may offer lower prices but could compromise on quality, leading to potential issues down the line.

Modern submerged pumps may come equipped with advanced features, such as variable speed drives, integrated sensors, and smart controls. These technological advancements can enhance efficiency and make operation safer and more convenient. However, pumps with these sophisticated features typically carry a higher price tag. Buyers must weigh the benefits of these advancements against their budget and specific needs.

submerged pump price

4. Material and Construction

The materials used in the construction of submerged pumps are crucial to their performance and price. Pumps made from high-grade stainless steel or corrosion-resistant materials tend to be more expensive but are often necessary for applications involving harsh liquids or environments. On the other hand, pumps made from lower-quality materials may offer lower prices but can lead to increased wear and tear over time, resulting in more frequent replacements or repairs.

5. Market Demand and Supply

Like any product, the prices of submerged pumps are influenced by supply and demand dynamics. During peak seasons for agricultural or construction activities, the demand for submersible pumps may increase, driving prices up. On the contrary, during economic downturns or off-seasons, prices may become more competitive as manufacturers and retailers look to boost sales.

6. Installation and Maintenance Costs

When considering the total cost of purchasing a submerged pump, it is crucial to consider installation and maintenance expenses. Some pumps may require specialized installation, which can add to overall costs. Additionally, maintenance requirements can vary significantly between models, with more advanced pumps generally necessitating more frequent upkeep. Potential buyers should factor these costs into their budget to avoid surprises.

Conclusion

When looking at submerged pump prices, it’s important to consider a multitude of factors, including type, brand, technology, materials, market conditions, and installation costs. By understanding these variables, potential buyers can make informed choices that align with their needs and budgets. Ultimately, investing in a submerged pump that balances quality, performance, and cost will yield the best long-term results for any application.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail