10 月 . 21, 2024 13:20 Back to list

Industrial Deep Water Pumps for Effective Submersion and Fluid Transfer Solutions

Industrial Submersible Pumps An Overview

Industrial submersible pumps are specialized devices designed to operate underwater for various applications in sectors such as water treatment, oil and gas, mining, construction, and agriculture. These pumps play a crucial role in transferring liquids, handling abrasive substances, and managing fluid levels in a wide range of environments, from wastewater treatment facilities to drilling sites.

One of the primary advantages of submersible pumps is their ability to function efficiently while completely submerged in the liquid they are pumping. This feature allows them to avoid issues related to cavitation, which can occur when a traditional surface pump struggles to draw fluid. By placing the pump underwater, less energy is required to move the fluid, translating to lower operational costs and greater efficiency. Additionally, submersible pumps are typically hermetically sealed units, protecting the motor from water damage and reducing the risk of corrosion, thereby enhancing the equipment's lifespan.

Industrial Submersible Pumps An Overview

The construction of a submersible pump usually includes a motor, a pump body, an impeller, and a discharge. The motor is connected directly to the impeller, which enables the pump to perform its functions effectively without any intermediary components. The entire assembly is designed for optimal durability and efficiency, often using high-quality materials to withstand the challenging conditions of underwater operations.

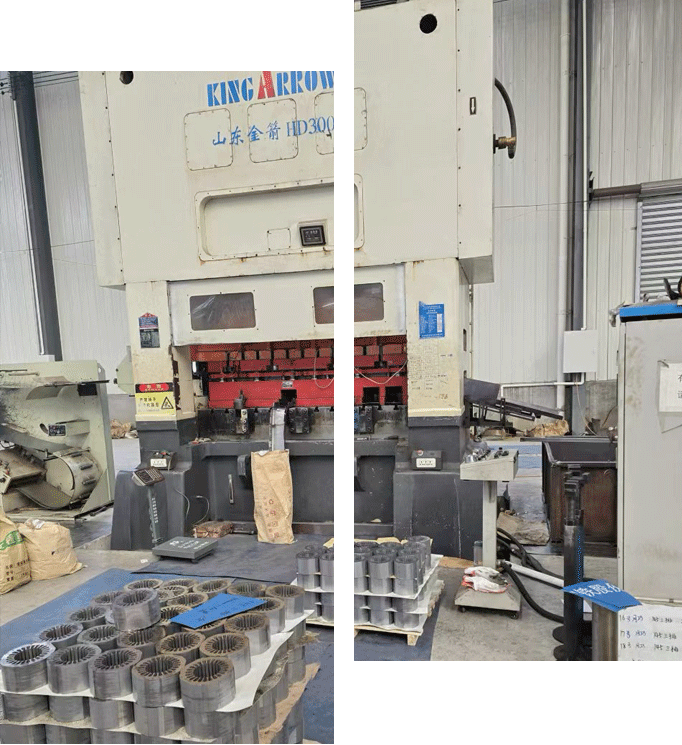

industrial submersible pumps

When selecting an industrial submersible pump, key factors must be considered, including flow rate, head (the height to which the pump can raise water), power consumption, and the nature of the liquid being pumped. It is essential to choose a pump that fits the specific application to ensure reliable performance and reduce the risk of breakdowns. Additionally, companies often look for pumps that offer advanced features such as automatic control systems, float switches, or built-in protection mechanisms to enhance safety and operational efficiency.

The maintenance of submersible pumps is vital to their longevity and performance. Regular inspection and servicing can prevent common issues such as wear and tear, overheating, and clogging. It’s essential to monitor the condition of components like seals and bearings and replace them as needed to maintain optimal functionality. Some modern submersible pumps now feature advanced diagnostic tools that provide real-time feedback on performance, simplifying the maintenance process.

Furthermore, as industries increasingly focus on sustainability, submersible pump manufacturers are innovating to enhance energy efficiency and reduce environmental impact. New technologies, such as variable frequency drives (VFDs), allow pumps to operate at different speeds based on demand, significantly lowering energy consumption.

In summary, industrial submersible pumps are indispensable tools in various sectors, contributing to efficient fluid management and facilitating numerous processes. Their efficient design, coupled with advancements in technology and materials, ensures that they meet the growing demands of modern industries. As markets continue to evolve, submersible pumps will likely play an even more prominent role in addressing challenges related to water management and resource conservation. Investing in the right submersible pump not only enhances operational efficiency but also contributes to a more sustainable future.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail