8 月 . 11, 2024 11:40 Back to list

Innovative Deep Well Multistage Submersible Pump Solutions for Efficient Water Supply Systems

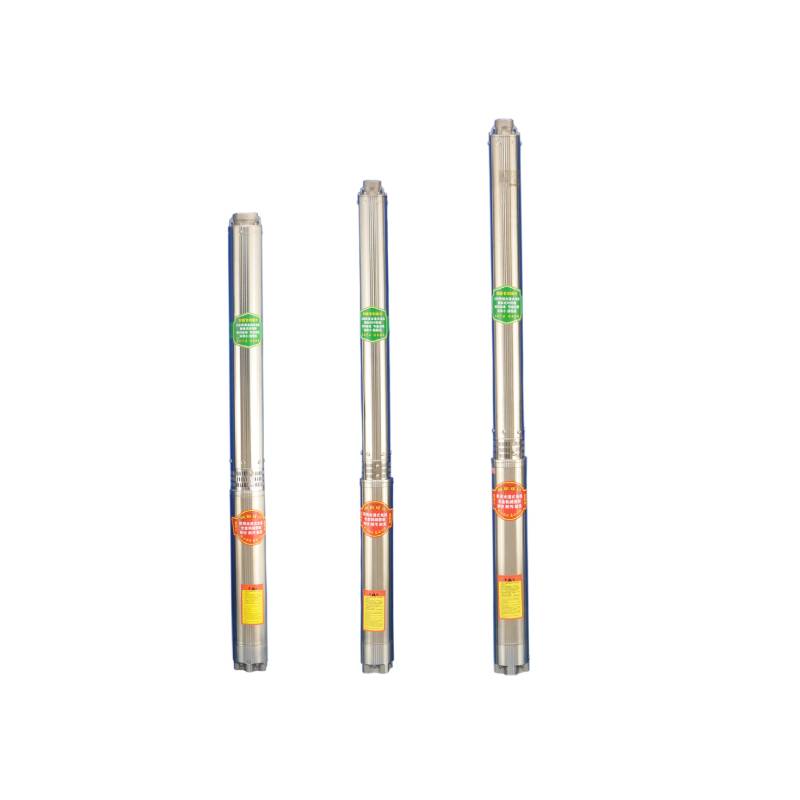

Deep Well Multistage Submersible Pumps An Overview

Deep well multistage submersible pumps are essential equipment in various applications, ranging from agricultural irrigation to municipal water supply and industrial processes. These pumps are designed to operate in deep wells, where traditional pumps might fail to provide the necessary water pressure or volume. This article explores the design, functionality, applications, and advantages of deep well multistage submersible pumps.

Design and Functionality

Deep well multistage submersible pumps consist of multiple impellers arranged in a series. This multistage configuration enables the pump to efficiently lift water from great depths. The pump is submerged in water, and its electric motor is located above the water level, driving the impellers through a vertical shaft. Typical designs allow these pumps to operate effectively at depths ranging from 100 to over 1,500 feet, depending on the specific model and application.

The primary components of a multistage submersible pump include the pump casing, impellers, diffusers, motor, and discharge head. The impellers are responsible for increasing the kinetic energy of the water, while the diffusers convert this kinetic energy into pressure. The combination of several stages results in significant pressure buildup, making these pumps ideal for deep-well applications.

Applications

Deep well multistage submersible pumps are widely used across various sectors. In agriculture, they supply water for irrigation in regions where surface water is scarce or where agricultural demands exceed available sources. Municipal water supply systems employ these pumps to extract groundwater for residential and commercial consumption, ensuring a steady flow even during peak demand.

deep well multistage submersible pump

Additionally, industrial applications such as cooling processes, boiler feed water supply, and fire protection systems utilize deep well pumps due to their reliability and efficiency. In the mining sector, these pumps help dewater mines and manage process water, contributing to operational efficiency and safety.

Advantages

One of the primary advantages of deep well multistage submersible pumps is their ability to deliver high pressure and flow rates from significant depths. This characteristic makes them indispensable for applications where gravitational flow is insufficient. Furthermore, the submersible design minimizes installation complexity and reduces the need for above-ground pump housing, which is beneficial in aesthetically-sensitive or space-constrained environments.

Another significant advantage is energy efficiency. Multistage pumps are designed to operate at optimal performance levels, reducing the energy consumption compared to conventional single-stage pumps. Many modern submersible pumps are also equipped with variable frequency drives (VFDs), allowing for precise control over pump speed and further enhancing energy efficiency.

Moreover, these pumps are known for their durability and reliability. Constructed from high-quality materials like stainless steel or corrosion-resistant alloys, they can withstand harsh environmental conditions and prolonged exposure to water, minimizing maintenance needs and extending operational lifespans.

Conclusion

Deep well multistage submersible pumps represent a critical technology for accessing and utilizing groundwater efficiently. Their robust design, high efficiency, and adaptability across various industries make them invaluable tools in addressing water supply challenges. As demand for water continues to rise, the role of these pumps becomes increasingly vital in promoting sustainable water management solutions. Whether for irrigation, municipal supply, or industrial applications, deep well multistage submersible pumps will continue to play a pivotal role in ensuring a reliable water supply, underpinning agricultural productivity, and supporting industrial processes.

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail