2 月 . 12, 2025 14:02 Back to list

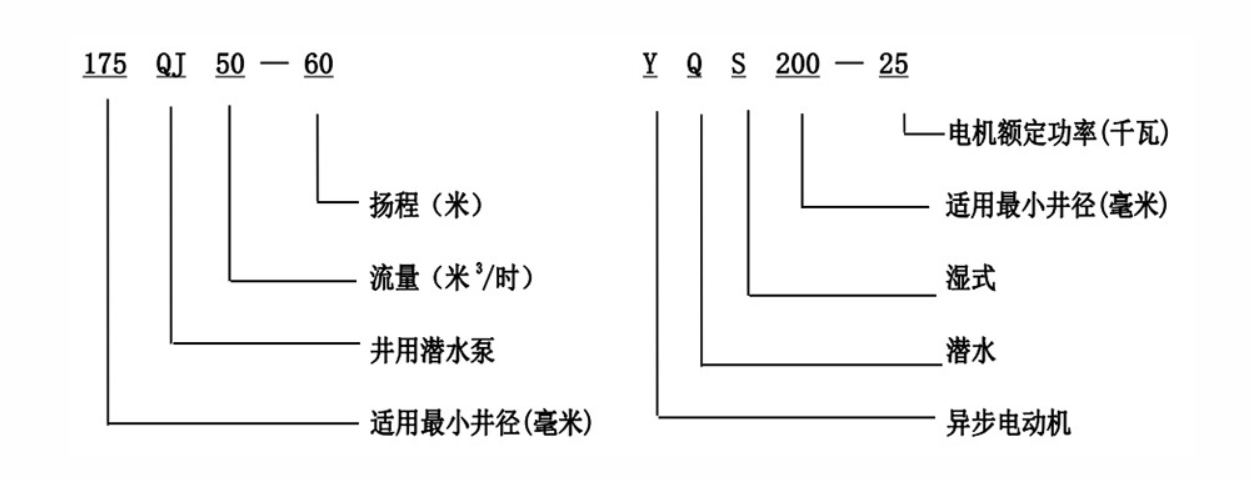

175QJ Deep Well Submersible Pump

Choosing the right submersible pump can significantly impact your project's efficiency and effectiveness. Submersible pumps are versatile, essential tools designed for a wide range of applications, from residential sump pumps to large-scale industrial uses. Their design allows them to be submerged in the fluid to be pumped, thus providing exceptional functionality in diverse environments.

Having worked closely with suppliers and manufacturers, I recommend looking for submersible pumps from companies that offer robust customer support and comprehensive warranties. The availability of replacement parts and ticked efficiency ratings also contribute to a pump's long-term reliability and performance. Trustworthiness in a submersible pump also stems from material quality. Pumps made from corrosion-resistant materials such as stainless steel or thermoplastics are particularly beneficial in abrasive or acidic environments. This ensures the pump’s durability and consistent performance, crucial for industries like mining or chemical processing where maintaining uptime is imperative. In practical terms, installing a submersible pump requires attention to detail. Safety provisions must be in place to prevent electrical hazards, especially in submerged installations. Insisting on professional installation services and adhering to local electrical codes can safeguard users and assets against risks. In conclusion, submersible pumps are an unmatched asset in fluid management across diverse industries. The key to maximizing their potential lies in selecting the right model tailored to your specific application, ensuring quality and manufacturer support, and observing stringent safety practices during installation and maintenance. With ongoing advancements in technology, these pumps will continue to evolve, offering greater efficiency, reduced energy consumption, and enhanced reliability. By prioritizing experience, expertise, authoritative sourcing, and diligent research, you can make informed decisions that ensure the success and cost-effectiveness of your pumping applications.

Having worked closely with suppliers and manufacturers, I recommend looking for submersible pumps from companies that offer robust customer support and comprehensive warranties. The availability of replacement parts and ticked efficiency ratings also contribute to a pump's long-term reliability and performance. Trustworthiness in a submersible pump also stems from material quality. Pumps made from corrosion-resistant materials such as stainless steel or thermoplastics are particularly beneficial in abrasive or acidic environments. This ensures the pump’s durability and consistent performance, crucial for industries like mining or chemical processing where maintaining uptime is imperative. In practical terms, installing a submersible pump requires attention to detail. Safety provisions must be in place to prevent electrical hazards, especially in submerged installations. Insisting on professional installation services and adhering to local electrical codes can safeguard users and assets against risks. In conclusion, submersible pumps are an unmatched asset in fluid management across diverse industries. The key to maximizing their potential lies in selecting the right model tailored to your specific application, ensuring quality and manufacturer support, and observing stringent safety practices during installation and maintenance. With ongoing advancements in technology, these pumps will continue to evolve, offering greater efficiency, reduced energy consumption, and enhanced reliability. By prioritizing experience, expertise, authoritative sourcing, and diligent research, you can make informed decisions that ensure the success and cost-effectiveness of your pumping applications.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail