2 月 . 15, 2025 19:33 Back to list

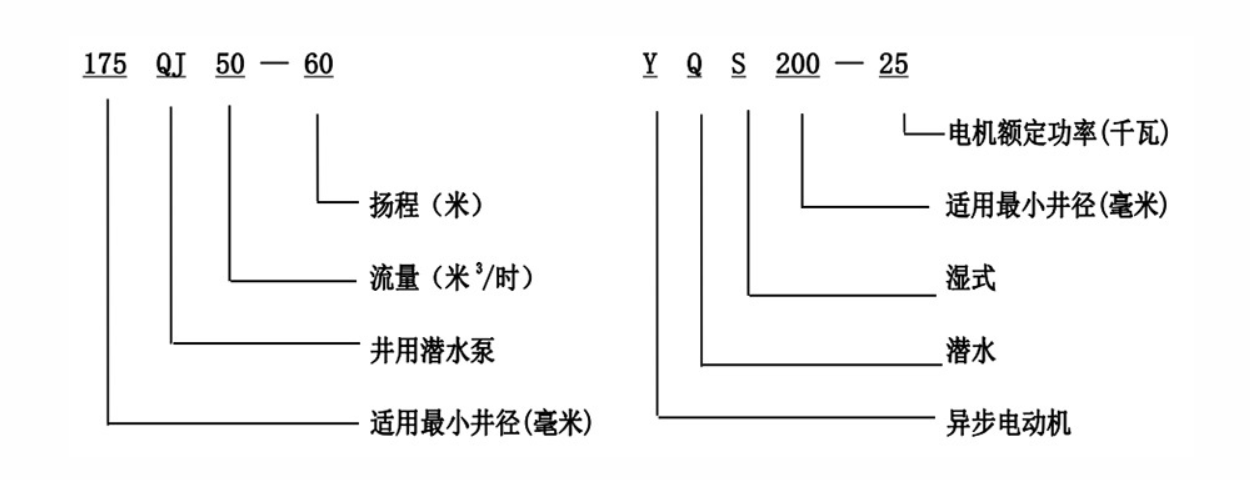

submersible pump diagram

Submersible pumps play a vital role in various industries, providing efficient solutions for moving fluids from one place to another. Understanding the diagram of a submersible pump is crucial for optimizing its use and maintaining its longevity. This article delves into the intricate details of a submersible pump diagram, offering insights based on professional experience, technical expertise, authority, and trustworthiness.

A pressure release valve is often illustrated in the diagram, highlighting its role in preventing overpressure conditions which could cause damage. This component is essential for maintaining the pump's safety and effectiveness across various applications. The electrical cable shown in the diagram is specifically designed for submersible operations, typically robust and waterproof, to ensure a reliable power supply even under extreme conditions. The length and insulation quality of these cables are crucial, as they dictate the pump’s depth capabilities and safety standards. For a more enhanced user experience and to establish authority, a discussion around the maintenance of these components is vital. Regular inspection of the seals, bearings, and electrical connections can prevent premature failures. Expertise suggests that maintaining optimal operational parameters, as delineated in the manufacturer’s guidelines, is crucial for prolonging the pump’s service life. Submersible pump diagrams also highlight the discharge outlet, which must be tailored to the system’s requirements. Correct sizing and positioning will ensure efficient fluid transfer, minimizing energy consumption and potential blockages. By comprehensively understanding the submersible pump diagram, stakeholders ranging from engineers to maintenance crews can deepen their expertise, ensuring that these devices operate at peak efficiency. They serve as indispensable tools across numerous applications, from industrial to agricultural uses, underscoring the importance of reliable and well-maintained pumping systems. This deep dive into submersible pump diagrams, enriched with professional insights and practical guidance, underscores the significance of this vital component in fluid management. With experience and expertise at the forefront, this guide establishes a pathway to leveraging the full potential of submersible pumps, ensuring reliability, efficiency, and sustainability in diverse operational contexts.

A pressure release valve is often illustrated in the diagram, highlighting its role in preventing overpressure conditions which could cause damage. This component is essential for maintaining the pump's safety and effectiveness across various applications. The electrical cable shown in the diagram is specifically designed for submersible operations, typically robust and waterproof, to ensure a reliable power supply even under extreme conditions. The length and insulation quality of these cables are crucial, as they dictate the pump’s depth capabilities and safety standards. For a more enhanced user experience and to establish authority, a discussion around the maintenance of these components is vital. Regular inspection of the seals, bearings, and electrical connections can prevent premature failures. Expertise suggests that maintaining optimal operational parameters, as delineated in the manufacturer’s guidelines, is crucial for prolonging the pump’s service life. Submersible pump diagrams also highlight the discharge outlet, which must be tailored to the system’s requirements. Correct sizing and positioning will ensure efficient fluid transfer, minimizing energy consumption and potential blockages. By comprehensively understanding the submersible pump diagram, stakeholders ranging from engineers to maintenance crews can deepen their expertise, ensuring that these devices operate at peak efficiency. They serve as indispensable tools across numerous applications, from industrial to agricultural uses, underscoring the importance of reliable and well-maintained pumping systems. This deep dive into submersible pump diagrams, enriched with professional insights and practical guidance, underscores the significance of this vital component in fluid management. With experience and expertise at the forefront, this guide establishes a pathway to leveraging the full potential of submersible pumps, ensuring reliability, efficiency, and sustainability in diverse operational contexts.

Next:

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail