2 月 . 20, 2025 10:05 Back to list

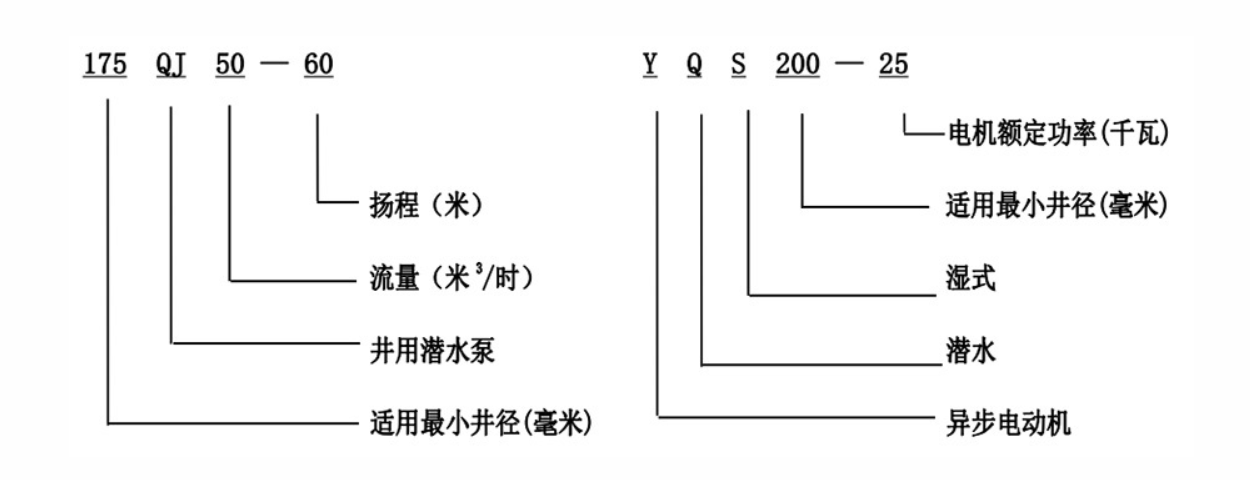

175QJ Deep Well Submersible Pump

The submersible tank pump is a pivotal component in industries and applications where efficient fluid management is crucial. As an experienced professional with extensive expertise in fluid dynamics and mechanical engineering, I've observed the transformative impact of submersible tank pumps across various sectors. This article aims to elucidate the unique benefits, applications, and considerations associated with these pumps, drawing on both authoritative sources and practical experience to ensure trustworthiness and authority.

In the oil and gas industry, submersible tank pumps are crucial in dewatering applications and managing the extraction process. Their robust design can handle the harsh conditions often associated with oil fields, such as corrosive fluids and abrasive materials. This durability and reliability enhance operational safety, a paramount concern in such high-stakes environments. Despite these robust advantages, selecting the appropriate submersible tank pump requires careful consideration of several factors. Industry professionals must evaluate the pump's material construction to ensure it is compatible with the fluid properties. Corrosion resistance, pressure ratings, and temperature thresholds are critical technical specifications that warrant careful scrutiny to optimize performance and durability. Additionally, energy consumption should not be overlooked. Advances in technology offer energy-efficient models that reduce the carbon footprint while providing substantial cost savings over the pump's lifecycle. Engaging with manufacturers and suppliers who prioritize innovation and sustainability is crucial for organizations aiming to enhance their environmental responsibility. In conclusion, submersible tank pumps are integral to modern fluid management solutions across various sectors, from wastewater treatment and agriculture to oil and gas. Their reliability, efficiency, and versatility make them a wise investment for industries aiming to optimize operational processes. For stakeholders considering the adoption or upgrade of pumping solutions, engaging with expert insights and reputable manufacturers ensures that each system is tailored to precise operational needs, thereby maximizing return on investment. The expertise drawn from the field assures that the submersible tank pump remains a cornerstone technology in efficient and sustainable fluid management.

In the oil and gas industry, submersible tank pumps are crucial in dewatering applications and managing the extraction process. Their robust design can handle the harsh conditions often associated with oil fields, such as corrosive fluids and abrasive materials. This durability and reliability enhance operational safety, a paramount concern in such high-stakes environments. Despite these robust advantages, selecting the appropriate submersible tank pump requires careful consideration of several factors. Industry professionals must evaluate the pump's material construction to ensure it is compatible with the fluid properties. Corrosion resistance, pressure ratings, and temperature thresholds are critical technical specifications that warrant careful scrutiny to optimize performance and durability. Additionally, energy consumption should not be overlooked. Advances in technology offer energy-efficient models that reduce the carbon footprint while providing substantial cost savings over the pump's lifecycle. Engaging with manufacturers and suppliers who prioritize innovation and sustainability is crucial for organizations aiming to enhance their environmental responsibility. In conclusion, submersible tank pumps are integral to modern fluid management solutions across various sectors, from wastewater treatment and agriculture to oil and gas. Their reliability, efficiency, and versatility make them a wise investment for industries aiming to optimize operational processes. For stakeholders considering the adoption or upgrade of pumping solutions, engaging with expert insights and reputable manufacturers ensures that each system is tailored to precise operational needs, thereby maximizing return on investment. The expertise drawn from the field assures that the submersible tank pump remains a cornerstone technology in efficient and sustainable fluid management.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail