2 月 . 20, 2025 12:04 Back to list

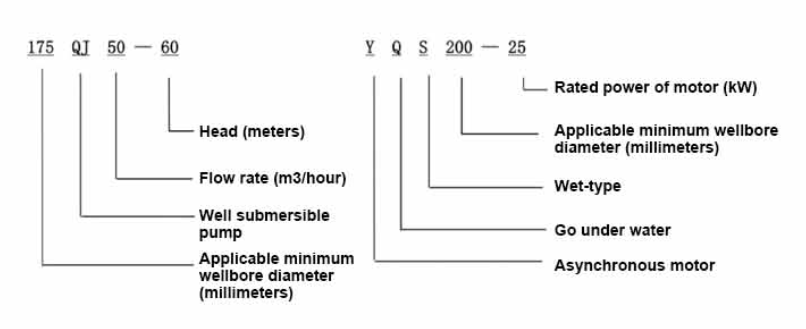

175QJ Deep Well Submersible Pump

Submersible well pumps are indispensable in ensuring a consistent water supply from underground sources, especially in areas where surface water is scarce. However, like any mechanical device, they are prone to certain problems that can disrupt their functioning. Understanding these issues and knowing how to address them is crucial for anyone relying on these pumps. This article explores common submersible well pump problems and provides expert insights into troubleshooting and preventive measures to ensure longevity and optimal performance.

Blockages and clogs within the pump or in the pipeline can also lead to interrupted water flow. This is usually caused by debris or build-up of minerals that restrict the movement of water. Regular inspections and cleaning of the pump and associated pipelines are essential preventive measures. If mineral build-up is severe, chemical treatments or professional cleaning might be necessary to restore normal water flow. One issue that can often be overlooked is corrosion, particularly in metallic components of the pump exposed to aggressive water conditions. Corrosion can weaken these parts, eventually leading to leaks or breaks. The use of corrosion-resistant materials during installation and regular checks for signs of corrosion can prevent unexpected failures. Seeking a professional's expertise is invaluable when dealing with complex problems beyond basic troubleshooting. Regular inspections by qualified technicians can identify potential problems before they escalate, ensuring that corrective measures are promptly applied. This not only extends the life of the pump but also ensures a reliable water supply. Submersible well pump problems, while varied, can often be mitigated with regular maintenance, proper installation, and timely intervention when issues arise. By understanding the common sources of these problems and implementing preventive strategies, users can ensure the efficient and effective operation of their submersible well pumps. Maintaining familiarity with the manufacturer's guidelines and engaging with professional services when necessary will underpin a robust and lasting pumping solution, reinforcing both trust and authority in submersible well pump usage.

Blockages and clogs within the pump or in the pipeline can also lead to interrupted water flow. This is usually caused by debris or build-up of minerals that restrict the movement of water. Regular inspections and cleaning of the pump and associated pipelines are essential preventive measures. If mineral build-up is severe, chemical treatments or professional cleaning might be necessary to restore normal water flow. One issue that can often be overlooked is corrosion, particularly in metallic components of the pump exposed to aggressive water conditions. Corrosion can weaken these parts, eventually leading to leaks or breaks. The use of corrosion-resistant materials during installation and regular checks for signs of corrosion can prevent unexpected failures. Seeking a professional's expertise is invaluable when dealing with complex problems beyond basic troubleshooting. Regular inspections by qualified technicians can identify potential problems before they escalate, ensuring that corrective measures are promptly applied. This not only extends the life of the pump but also ensures a reliable water supply. Submersible well pump problems, while varied, can often be mitigated with regular maintenance, proper installation, and timely intervention when issues arise. By understanding the common sources of these problems and implementing preventive strategies, users can ensure the efficient and effective operation of their submersible well pumps. Maintaining familiarity with the manufacturer's guidelines and engaging with professional services when necessary will underpin a robust and lasting pumping solution, reinforcing both trust and authority in submersible well pump usage.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail