2 月 . 19, 2025 10:02 Back to list

175QJ Deep Well Submersible Pump

Installing a submersible pump may seem daunting, especially for those unfamiliar with water management systems. However, with the right guidance, it becomes manageable, ensuring efficiency and reliability in both residential and commercial applications. This article provides a comprehensive, step-by-step guide to installing a submersible pump, based on professional expertise and authoritative sources, to guarantee an experience of success and trust.

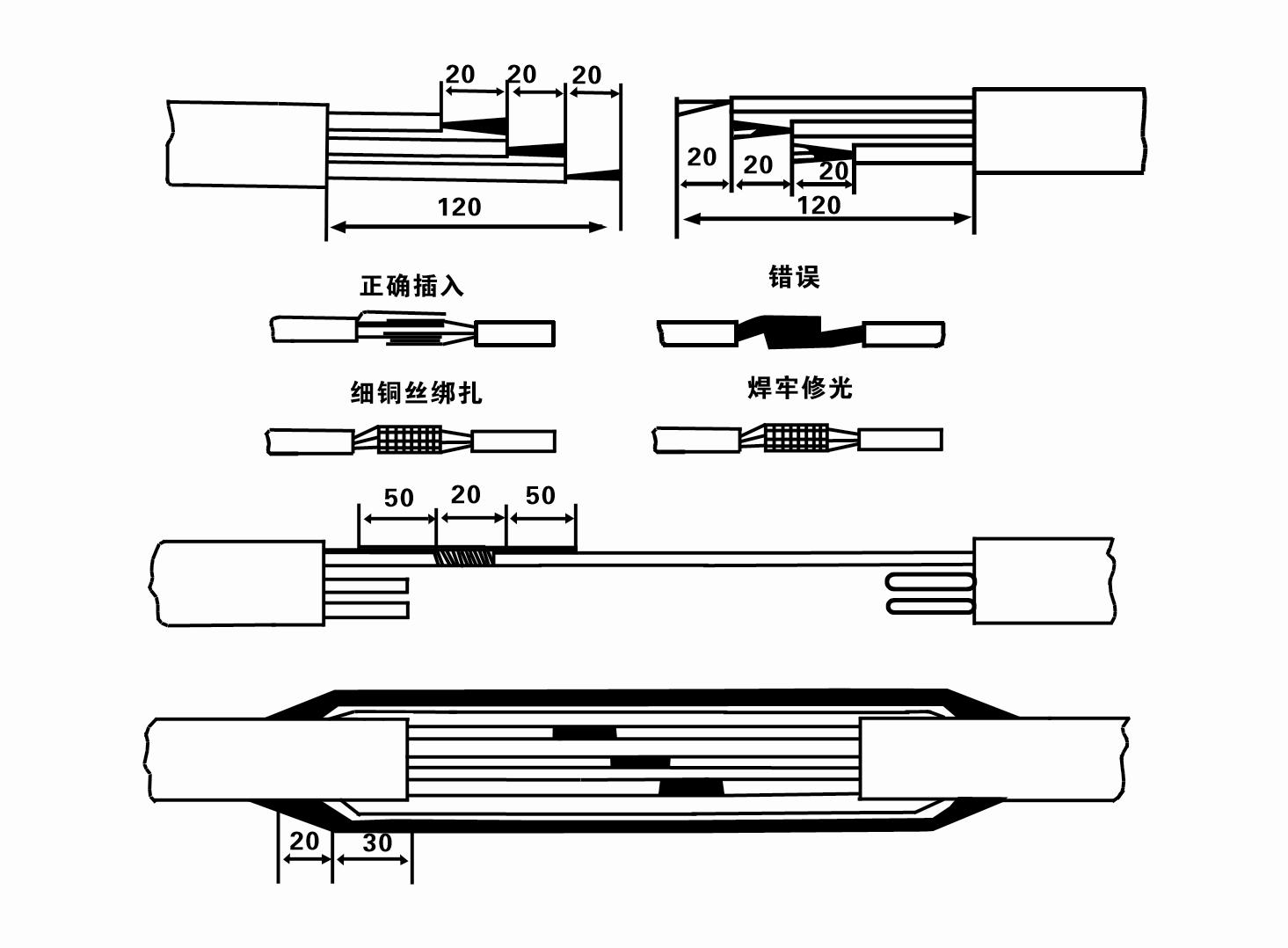

Step 5 Assemble the Pump System Join the pump to the drop pipe using the manufacturer-approved coupling method, usually via threaded connections or adaptors. Connect the electrical cable to the pump’s terminal box using the gland provided. Ensure the cable diameter matches the gland to prevent ingress of water, maintaining the authority of your craftsmanship. Step 6 Installing in the Water Source Carefully lower the pump into the water source, ensuring it remains vertical to avoid mechanical failure. Secure the pump with a safety cable to a secure point outside the well for easy retrieval during maintenance. This authoritative step reassures the longevity of the pump system. Step 7 Finalizing the Installation Once the pump is placed correctly, connect the other end of the drop pipe to a pressure tank or a water delivery system. Conduct a pressure test to ensure all connections are secure with no leaks present. Implementing a thorough test demonstrates expertise and instills confidence in the pump's utility. Step 8 Operational Testing After confirming the installation steps, turn on the electrical power to test the pump's operation. Monitor the pump's performance concerning pressure consistency and flow rate. Adjust settings in the control box as per your system’s requirement. Documenting performance tests ensures the pump's efficiency and provides a reliable reference for future maintenance. Conclusion Successfully installing a submersible pump requires careful attention to safety measures, precise measurements, and adherence to both manufacturer guidelines and local regulations. Combining technical expertise with comprehensive testing fosters trust in your capability to deliver reliable water management solutions. Always consult professional resources or seek more experienced help if uncertainties arise. By following this guide, you not only enhance your skills but also establish an authoritative presence in sustainable water solutions.

Step 5 Assemble the Pump System Join the pump to the drop pipe using the manufacturer-approved coupling method, usually via threaded connections or adaptors. Connect the electrical cable to the pump’s terminal box using the gland provided. Ensure the cable diameter matches the gland to prevent ingress of water, maintaining the authority of your craftsmanship. Step 6 Installing in the Water Source Carefully lower the pump into the water source, ensuring it remains vertical to avoid mechanical failure. Secure the pump with a safety cable to a secure point outside the well for easy retrieval during maintenance. This authoritative step reassures the longevity of the pump system. Step 7 Finalizing the Installation Once the pump is placed correctly, connect the other end of the drop pipe to a pressure tank or a water delivery system. Conduct a pressure test to ensure all connections are secure with no leaks present. Implementing a thorough test demonstrates expertise and instills confidence in the pump's utility. Step 8 Operational Testing After confirming the installation steps, turn on the electrical power to test the pump's operation. Monitor the pump's performance concerning pressure consistency and flow rate. Adjust settings in the control box as per your system’s requirement. Documenting performance tests ensures the pump's efficiency and provides a reliable reference for future maintenance. Conclusion Successfully installing a submersible pump requires careful attention to safety measures, precise measurements, and adherence to both manufacturer guidelines and local regulations. Combining technical expertise with comprehensive testing fosters trust in your capability to deliver reliable water management solutions. Always consult professional resources or seek more experienced help if uncertainties arise. By following this guide, you not only enhance your skills but also establish an authoritative presence in sustainable water solutions.

Latest news

-

Your Guide to Deep Well Pumps

NewsOct.31,2024

-

Why Choose a Stainless Steel Deep Well Pump?

NewsOct.31,2024

-

Understanding Water-Filled Submersible Pumps

NewsOct.31,2024

-

Understanding SS Submersible Pumps

NewsOct.31,2024

-

Reliable Submersible Well Pumps for Your Water Supply Needs

NewsOct.31,2024

-

Choosing the Right Submersible Pump for Your Water Management Needs

NewsOct.31,2024

-

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail

Understanding Water-Filled Submersible PumpsWhen it comes to selecting the right pump for your water management needs, understanding the different types available is crucial.Detail -

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail

Guide to Installing a Deep Well Submersible PumpWhen dealing with deep wells, a deep well submersible pump is often the most effective solution for extracting water from significant depths.Detail -

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail

Finding the Right Submersible PumpWhen seeking an efficient solution for pumping water from deep wells, sumps, or other applications, the submersible pump is a leading choice.Detail